Solid-state Batteries Report

: Analysis on the Market, Trends, and TechnologiesThe solid-state battery market is on a rapid commercialization path: the internal trend data forecasts a market of US $9.8 billion by 2030 and reports a 32.0% CAGR, driven primarily by electric-vehicle demand and targeted R&D in electrolyte and interface engineering. External industry studies confirm steep growth expectations and place near-term commercialization milestones for premium EVs and microbattery devices, reinforcing that the next three years will determine whether process scale and interface durability move SSBs from pilots into volume manufacturing.

90 days ago, we last updated this report. Notice something that’s not right? Let’s fix it together.

Topic Dominance Index of Solid-state Batteries

To gauge the influence of Solid-state Batteries within the technological landscape, the Dominance Index analyzes trends from published articles, newly established companies, and global search activity

Key Activities and Applications

- Electric vehicle battery systems — development of automotive-scale cells and packs that target higher energy density and faster charging while meeting OEM durability protocols.

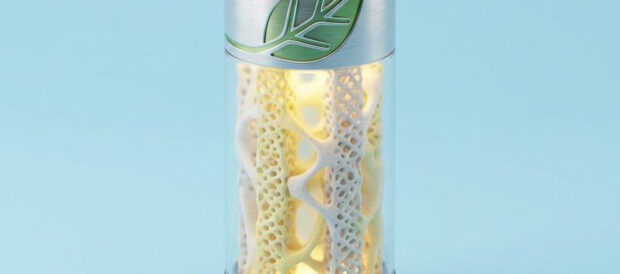

- Portable and wearable microbatteries — thin-film and micro-cell designs optimized for safety and form factor in medical devices, wearables, and IoT nodes Solid-State Micro Battery Market Research Report.

- Stationary and grid support — larger-format solid-state or semi-solid packs for long-duration storage and renewable integration where lifecycle and safety matter more than lowest cost.

- Materials and interface R&D — intensive laboratory work on sulfide/oxide/polymer electrolytes, interlayer coatings and dendrite suppression to reach automotive cycle-life targets Advancements and Challenges in Solid-State Battery Technology.

- Manufacturing process development — low-temperature densification, cold-sintering, roll-to-roll coating, and hot-press assembly trials intended to convert lab cells into high-yield production parts.

Emergent Trends and Core Insights

- Manufacturing and interfaces now determine commercial timing — patent and corporate activity show >60% of recent filings focus on interface engineering and manufacturability, implying process yield, not single-material performance, will gate mass adoption.

- Multiple credible market forecasts but different horizons — short-term forecasts (2024–2031) show small base values and steep CAGRs; longer-horizon reports project multi-billion markets by 2034–2036, reflecting uncertainty tied to scale vs. lab performance (see comparative table below) Solid-State Battery Market Size & Share, Trends & Forecast to 2034.

- Technology bifurcation: sulfide vs oxide vs polymer paths — sulfides favor conductivity and manufacturability but require dry handling; oxides offer stability but need high-temp processing; polymers offer process compatibility but lower ambient conductivity. Firms choose path by target application (EV vs microbattery).

- Near-term commercial plays are hybrid/semi-solid systems — semi-solid and quasi-solid approaches allow leverage of existing Li-ion lines and shorten time to pilot production Semi Solid State Battery Market Size - By Application, Growth Forecast, 2025 - 2034.

- Regional R&D and supply concentration — Asia-Pacific (Japan, South Korea, China) leads material-level IP and pilot lines while U.S. and EU push manufacturing clusters and OEM partnerships; this creates geopolitically sensitive supply chains for sulfide precursors and dry-room capacity Global solid-state battery market will experience a 38.2% CAGR.

Technologies and Methodologies

- Sulfide solid electrolytes (high ionic conductivity; sensitive to moisture) — favored for high power and lower-temperature processing but require supply and dry-handling solutions.

- Oxide/garnet electrolytes (e.g. LLZO) — deliver chemical stability and thermal tolerance; current work focuses on ultra-thin ALD coatings to lower interfacial resistance.

- Polymer and composite electrolytes — enable flexible, thin-film cells and potential use of existing coating lines; research improves ionic mobility at room temperature.

- Lithium-metal and silicon anodes — paired with SSEs to unlock >400 Wh/kg cell targets; interface coatings and engineered interlayers mitigate dendrite growth and volume change Advancements and Challenges in Solid-State Battery Technology.

- Manufacturing innovations — cold sintering, in-situ curing/hot pressing and roll-to-roll deposition reduce thermal budgets and enable continuous processing for scale 'Cold' manufacturing approach solves fabrication challenge for solid-state batteries.

- Cell-level diagnostics and spectroscopy QC — integrating Raman/other spectroscopic fingerprints into process control to enforce batch consistency at scale.

Solid-state Batteries Funding

A total of 160 Solid-state Batteries companies have received funding.

Overall, Solid-state Batteries companies have raised $35.1B.

Companies within the Solid-state Batteries domain have secured capital from 698 funding rounds.

The chart shows the funding trendline of Solid-state Batteries companies over the last 5 years

Solid-state Batteries Companies

- Ampcera — Materials specialist producing nano-sulfide solid electrolytes and shipping product samples into pilot lines; Ampcera's electrolyte focus addresses a key supply bottleneck for sulfide SSBs and is explicitly noted in market tracking as a supplier enabling pilot production.

- BasqueVolt — Regional battery integrator developing medium-format modules and partnering with local OEMs for grid and industrial pilots; the company represents a business model that targets high-value, low-volume stationary and specialty mobility applications where SSB safety and cycle life pay off.

- ZakuroBattery — Early-stage developer focusing on interface coatings and thin-film cell stacks for microbatteries; their technical scope maps to microbattery opportunities (wearables and medical) that offer earlier monetization than full EV packs.

- Solithor — Materials-to-cell startup emphasizing tailored polymer composites for quasi-solid cells that can run on conventional coating lines; this "semi-solid" pathway is highlighted by industry analysts as a near-term route to deployment.

- NanoCamp — Focuses on engineered anode microstructures and protective interlayers that reduce volumetric stress for high-capacity silicon anodes in SSBs; this component-level specialization aligns with patent trends that show heavy emphasis on interface and negative-electrode engineering.

Get detailed analytics and profiles on 647 companies driving change in Solid-state Batteries, enabling you to make informed strategic decisions.

647 Solid-state Batteries Companies

Discover Solid-state Batteries Companies, their Funding, Manpower, Revenues, Stages, and much more

Solid-state Batteries Investors

TrendFeedr’s Investors tool provides an extensive overview of 911 Solid-state Batteries investors and their activities. By analyzing funding rounds and market trends, this tool equips you with the knowledge to make strategic investment decisions in the Solid-state Batteries sector.

911 Solid-state Batteries Investors

Discover Solid-state Batteries Investors, Funding Rounds, Invested Amounts, and Funding Growth

Solid-state Batteries News

Explore the evolution and current state of Solid-state Batteries with TrendFeedr’s News feature. Access 3.4K Solid-state Batteries articles that provide comprehensive insights into market trends and technological advancements.

3.4K Solid-state Batteries News Articles

Discover Latest Solid-state Batteries Articles, News Magnitude, Publication Propagation, Yearly Growth, and Strongest Publications

Executive Summary

Solid-state batteries have shifted from "what" to "how": the pressing questions are process yield, interface durability, and supply-chain resilience rather than single-material energy claims. Quantitative signals in the internal data (a 32.0% CAGR and a near-term $9.8 billion forecast to 2030) paired with multiple independent market studies indicate strong commercial potential that will open in staged steps — microbatteries and high-margin premium EVs first, followed by broader automotive and stationary applications as manufacturing scale and interfacial reliability improve. Strategic priorities for firms and investors are clear: secure access to high-purity electrolyte precursors, validate repeatable low-defect manufacturing processes, and control the interface IP and testing protocols that automotive OEMs will require for product acceptance. Achieving those three objectives will determine which players capture value as the market moves from pilot to production.

We're looking to collaborate with knowledgeable insiders to enhance our analysis of trends and tech. Join us!