Industry 4.0 Report

: Analysis on the Market, Trends, and TechnologiesThe Industry 4.0 transition is entering a consolidation phase where platform plays and contextual data layers capture the majority of value, driven by an internal-sector compound growth estimate of 21.6% (CAGR) for the Industry 4.0 market. Market-size estimates vary by methodology—ranging from USD 146.14 billion (2022) to above USD 550 billion (2024) in independent reports—yet all sources converge on sustained double-digit growth and heavy investment in IIoT, AI, edge computing, and robotics grandviewresearch – Industry 4.0 Market, 2023. The strategic imperative for vendors and manufacturers is clear: move beyond raw data capture into low-code/AI-driven contextualization, integrate secure edge-cloud architectures, and position offerings as recurring-service infrastructure to capture the migration of margins from hardware to service and insight.

The last update of this report was 17 days ago. If you spot incomplete or incorrect info, please let us know.

Topic Dominance Index of Industry 4.0

The Topic Dominance Index analyzes the time series distribution of published articles, founded companies, and global search data to identify the trajectory of Industry 4.0 relative to all known Trends and Technologies.

Key Activities and Applications

- Predictive Maintenance and Condition Monitoring — Deploying IIoT sensors and ML models to shift maintenance from calendar-based to condition-based, reducing unplanned downtime and parts cost. This remains the highest-adoption revenue use case in manufacturing and energy sectors databridemarketresearch - Global Industry 4.0 Market, 2025.

- Digital Twin Deployment for Simulation and Planning — Creating synchronized virtual replicas of assets, lines, or plants to run scenario testing, accelerate commissioning, and shorten design-to-production cycles; digital twins drive faster root-cause analysis and planning savings

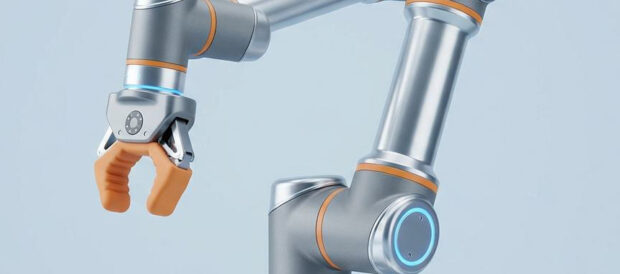

- Autonomous Material Handling and AMRs — Autonomous mobile robots and AGVs for intra-plant logistics and warehouse automation; yields lower OPEX for high-mix, fast-turn facilities and accelerates lot-size-one manufacturing strategies market.us - Global Industry 4.0 Market, 2024.

- AI-Vision Quality Assurance — Real-time visual inspection and defect prevention using edge inference to increase yield and reduce scrap; this activity is now measurable at scale and replaces slow manual QC loops

- Connected Worker and Augmented Operations — Mobile and AR tools that connect operators to contextual procedures and remote experts, increasing first-time-fix rates and shortening training time for complex tasks marketresearchfuture - Industry 4.0 Market, 2025.

- OT/IT Convergence and DataOps — Integration projects that standardize industrial data models and automate flow from PLCs to analytics platforms; this activity is the gating factor for enterprise-scale rollouts

Emergent Trends and Core Insights

- Platform consolidation is accelerating: companies that provide low-friction contextualization layers (no-code/low-code, DataOps) are increasingly strategic partners for manufacturers, because data without contextual models fails to produce ROI at scale gminsights - Industry 4.0 Market, 2025.

- Edge-first architectures are standard for mission-critical control: edge computing reduces latency and preserves operational continuity, enabling closed-loop control that hybrid cloud cannot guarantee alone IDC perspective on dedicated cloud infrastructure.

- Interoperability is the battleground: OPC UA, AAS workstreams, and open alliances are becoming procurement filters for OEMs and system integrators, because vendor lock-in adds integration cost and time Open Industry 4.0 Alliance.

- Cyber-physical security as a competitive requirement: OT-tailored, non-intrusive threat detection and electrically-derived signal monitoring are moving from optional to required features in supplier evaluations

- Service-first monetization: converting installed machinery into recurring revenue through digital services (predictive warranties, remote performance subscriptions) materially expands aftermarket margins vs single hardware sales Autonoma.

- Regional divergence persists: Asia-Pacific continues to deliver the largest revenue share and fastest deployment cadence, while North America leads in large-scale platform investments and private 5G adoption researchandmarkets - Industry 4.0 Market Outlook, 2025.

Technologies and Methodologies

- Industrial Internet of Things (IIoT) with multi-protocol edge gateways and device models; IIoT remains the core data fabric for sensing and actuation.

- Digital Twins (physics-hybrid + AI) used for predictive maintenance, virtual commissioning, and scenario planning; twin fidelity and real-time streaming determine utility

- Edge-Cloud Hybrids orchestrating control loops at the edge and analytics in the cloud to meet latency, sovereignty, and scale requirements marketdataforecast - Global Industry 4.0 Market.

- No-Code / Low-Code DataOps enabling domain engineers to build dashboards, rules, and integrations without heavy IT lead times; this reduces time-to-value and procurement friction HighByte.

- AI at the Edge (lightweight inference + federated learning) to support high-frequency decisioning on the shop floor while preserving data governance.

- Industrial Connectivity & Private Wireless (5G/LTE/LPWAN) for deterministic data transport in automated cells and wide-area sensing networks.

Industry 4.0 Funding

A total of 3.7K Industry 4.0 companies have received funding.

Overall, Industry 4.0 companies have raised $130.4B.

Companies within the Industry 4.0 domain have secured capital from 13.7K funding rounds.

The chart shows the funding trendline of Industry 4.0 companies over the last 5 years

Industry 4.0 Companies

- Leanworx Technologies Pvt. Ltd. Leanworx Technologies Pvt. Ltd.

Leanworx provides shop-floor machine monitoring that delivers OEE gains and rapid CapEx deferral for SMEs; customers report up to 70% downtime reductions by instrumenting legacy machines and closing the data gap into ERP systems. Their value proposition is a low-cost, high-ROI retrofit path that helps brownfield plants avoid major rewiring projects while generating immediate production KPIs. - i4Twins i4Twins

i4Twins offers a no-code digital-twin builder and runtime that enables frontline engineers to model assets, create rules and visualization without developer cycles; this compresses pilot-to-scale timelines and reduces the dependency on central IT. Their platform is engineered for rapid deployment in discrete manufacturing lines and supports OTA firmware and device management - Industrility Industrility

Industrility sells an AI-driven aftermarket and service platform that converts installed-base telemetry into recurring revenue streams for OEMs, including digital warranties and 3D parts commerce. Their focus on monetizing service lifecycles offers equipment makers a clear path from product sale to subscription income, improving lifetime customer economics - AIoTrust AIoTrust

AIoTrust delivers a non-intrusive electrical-signal sensing approach to detect PLC-level anomalies and cyber threats in OT environments. This product is designed to be installed without network changes, appealing to risk-averse operators who must harden legacy systems without interrupting production. Positioning cybersecurity as an operational necessity, AIoTrust addresses a fast-growing procurement filter for Industry 4.0 projects - Smart Track S.R.L. Smart Track S.R.L.

Smart Track focuses on connected-worker safety: wearables, geofencing, and anti-collision systems that integrate with factory automation to protect personnel in mixed human-robot environments. Their specialization in safety and compliance helps manufacturers meet regulatory obligations and reduces the operational risk that often blocks higher automation levels

TrendFeedr’s Companies tool is an exhaustive resource for in-depth analysis of 42.7K Industry 4.0 companies.

42.7K Industry 4.0 Companies

Discover Industry 4.0 Companies, their Funding, Manpower, Revenues, Stages, and much more

Industry 4.0 Investors

The TrendFeedr’s investors tool features data on 12.2K investors and funding activities within Industry 4.0. This tool makes it easier to analyze complex investment patterns and assess market potential with thorough and up-to-date financial insights.

12.2K Industry 4.0 Investors

Discover Industry 4.0 Investors, Funding Rounds, Invested Amounts, and Funding Growth

Industry 4.0 News

Stay ahead of the curve with Trendfeedr’s News feature. The tool provides access to 80.6K Industry 4.0. Navigate the current business landscape with historical and current Industry 4.0 data at your fingertips.

80.6K Industry 4.0 News Articles

Discover Latest Industry 4.0 Articles, News Magnitude, Publication Propagation, Yearly Growth, and Strongest Publications

Executive Summary

Industry 4.0 has moved from novelty pilots to enterprise architecture decisions. The most durable sources of future margin lie in contextual data layers, edge-capable control, and service models that convert installed machines into recurring revenue. Vendors and manufacturers must rework product roadmaps around accessibility (no-code), security (OT-first), and commercial flexibility (subscription and outcome pricing). The companies that win will be those that reduce implementation friction for customers and make industrial data both trustworthy and directly monetizable.

If you’re an expert in trends or emerging tech, we invite you to contribute to our insights.