Printing Technologies Report

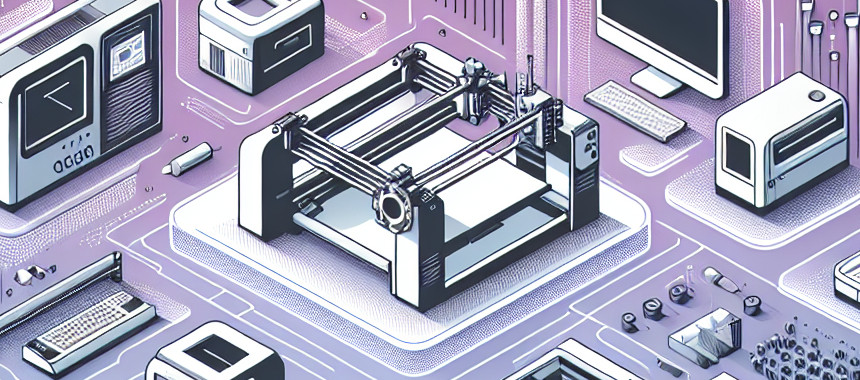

: Analysis on the Market, Trends, and TechnologiesThe printing technologies sector is shifting from commodity document output to application-led, materials-and-software integrated production, driven by a large installed base and fast adoption of new use cases: there are 53,183 companies working on printing technologies globally, according to the internal trend dataset, which frames scale and competitive pressure for service and materials innovation. Market evidence shows strong demand for specialized segments (for example, the inkjet printing market was estimated at USD 108.73 billion in 2024) and faster growth for functional and industrial printing niches, which creates distinct near-term commercial paths for equipment vendors, ink and consumable suppliers, and software/platform providers

The last time we updated this report was 79 days ago. If there’s something missing or off, your tips are welcome!

Topic Dominance Index of Printing Technologies

The Dominance Index for Printing Technologies merges timelines of published articles, newly founded companies, and global search data to provide a comprehensive perspective into the topic.

Key Activities and Applications

- High-precision functional printing: deposition of conductive, dielectric, or bioactive inks for printed electronics, sensors, and medical assays. This converts printers into direct functional-manufacturing tools rather than image reproducers, increasing value per square meter printed.

- Additive manufacturing for tooling and short-run production: using industrial-grade additive printers to produce jigs, fixtures, and small volume end parts reduces lead time and tooling expense relative to traditional subcontracting models

- On-demand, localized packaging and labels: short-run digital presses and hybrid systems enable regional personalization and rapid SKU changes to match e-commerce and retail demand patterns Printer - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030).

- Secure authentication and traceable printing: printing integrated with microstructure patterns, NFC tags, and printable security inks to provide verifiable provenance for pharmaceuticals and luxury goods, addressing regulatory and anti-counterfeit requirements

- Intelligent labeling and inline data capture: labels and codes that feed operational and supply-chain analytics, reducing waste and improving traceability on production lines Print technology: Latest Innovations And Trends - Gelato.

Emergent Trends and Core Insights

- Material science plus software defines differentiation: patent and market data show competition shifting from mechanical speed to ink chemistry, curing control, and algorithmic process control; vendors that combine proprietary inks with closed-loop process control gain pricing power.

- Industrial inkjet and hybrid systems capture structural demand: industrial inkjet is forecast to grow toward double digit billions by the end of the decade as food, pharma, and packaging apply digital marking and variable data requirements Industrial Inkjet Printers Report researchandmarkets - 2024.

- Distributed, cloud-managed printing networks: manufacturers and brand owners adopt cloud print management and secure workflows that allow consistent quality across distributed production nodes, improving resilience to supply chain shocks U.S. and Worldwide Production Printer Forecast, 2025–2028.

- Sustainability imposes technical constraints and market winners: water-based and UV-curable chemistries, closed-loop polymer recycling, and lower-VOC formulations become purchase criteria for enterprise customers, and regulatory pressure accelerates adoption in Europe and parts of APAC

- Move from incremental quality engineering to new deposition architectures: patent activity peaked 2021-2022 and reveals that incremental masking and multi-pass fixes carry rising R&D costs; the field is moving toward fundamentally different printhead and curing architectures to remove long-standing artifacts.

Technologies and Methodologies

- Drop-on-Demand and high-viscosity industrial inkjet: continued improvements in piezo and thermal DOD printheads allow higher-resolution deposition and handling of functional and pigmented inks for packaging and electronics

- Aerosol Jet Printing (AJP) and micro-deposition: enables fine-feature conductive traces and sensors on flexible substrates for printed electronics and IoT components.

- Volumetric Additive Manufacturing (VAM) and multi-material jetting: VAM and multi-material photopolymer jetting deliver speed and multi-material capability needed for rapid production of complex parts and tooling, reducing post-processing cycles Inkbit.

- Inline machine vision and digital twins for process control: 3D calibration and sensor fusion reduce misprints on nonplanar objects and enable predictable multi-layer functional printing.

- Aqueous and UV-curable ink chemistries tailored for specific substrates: these chemistries reduce VOC exposure and expand compatible substrates for flexible packaging and textile applications DuPont to Showcase New Innovative Artistri® Digital Printing Inks at drupa 2024

Printing Technologies Funding

A total of 2.8K Printing Technologies companies have received funding.

Overall, Printing Technologies companies have raised $41.1B.

Companies within the Printing Technologies domain have secured capital from 5.7K funding rounds.

The chart shows the funding trendline of Printing Technologies companies over the last 5 years

Printing Technologies Companies

- Tracxon — Tracxon focuses on printed sensor systems and flexible electronic integration for packaging and industrial monitoring. The company emphasizes customizable printed sensor inks and low-cost roll-to-roll production tooling, targeting supply-chain and logistics customers requiring embedded condition monitoring; this aligns with the printed electronics growth profile and demand for traceable packaging.

- Flexoo — Flexoo develops conductive and functional ink formulations for mid-volume printed electronics and rapid prototyping. Their product set emphasizes solvent-reduced formulations that simplify integration into industrial inkjet lines and support printed antenna and sensor manufacturing use cases.

- GeneSink — GeneSink targets bio-inkjet deposition for diagnostics and microarray manufacturing, combining biomaterials expertise with precision dispensing to create assay substrates used in lab automation. The approach addresses medical device miniaturization needs and aligns with medical printed electronics and biofabrication activity documented in the trends data.

- CopPrint — CopPrint builds modular finishing and inline inspection modules that bolt onto existing production inkjet lines to add finishing, coding, and vision-based quality checks. Their model addresses the demand for automation and finishing integration to create continuous production cells for packaging and label work.

Delve into the corporate landscape of Printing Technologies with TrendFeedr’s Companies tool

65.5K Printing Technologies Companies

Discover Printing Technologies Companies, their Funding, Manpower, Revenues, Stages, and much more

Printing Technologies Investors

TrendFeedr’s Investors tool provides insights into 4.8K Printing Technologies investors for you to keep ahead of the curve. This resource is critical for analyzing investment activities, funding trends, and market potential within the Printing Technologies industry.

4.8K Printing Technologies Investors

Discover Printing Technologies Investors, Funding Rounds, Invested Amounts, and Funding Growth

Printing Technologies News

TrendFeedr’s News feature offers you access to 18.6K articles on Printing Technologies. Stay informed about the latest trends, technologies, and market shifts to enhance your strategic planning and decision-making.

18.6K Printing Technologies News Articles

Discover Latest Printing Technologies Articles, News Magnitude, Publication Propagation, Yearly Growth, and Strongest Publications

Executive Summary

Printing technologies now split into two commercial tracks: high-volume commodity printing that seeks incremental cost and efficiency gains, and higher-margin application-specific printing that fuses materials science, digital control, and service models. Key strategic actions for incumbents and entrants are clear from the data: focus R&D and commercial investment on proprietary ink and consumable formulations tied to validated process controls; offer machine-plus-materials subscription models to convert capital sales into recurring revenue; and embed sensing, cloud management, and supply-chain integration to enable distributed production while ensuring consistent quality. Firms that secure IP and supply chains around functional inks, multi-material deposition hardware, and the software layers that control curing and registration will capture the expanding demand in packaging, textile, printed electronics, and medical printing markets.

Are you an insider in the trends or tech industry? We’d love for you to contribute to our content.